December 23, 2022

Development of Digital Solutions for Petroleum Engineering Domains

Digital Petroleum Engineer (PE) project was intended to support the client for its daily production-related activities together with helping the client to build its digital products.

Petroleum engineering-related activities were involving:

- Daily monitoring of producer wells, and separators, communicating with offshore about adjusting well parameters and obtaining samples from the wells.

- Optimizing production by changing well parameters or altering wells from low or high-pressure separator conditions.

- Planning, acceptance and analysis of well tests

- Allocation correction of wells

- Choke erosion calculation, interpretation and sharing results with the mechanical engineering team

- Well Model update on Prosper as per well test results

- Updating and modifying required elements in Prosper models

Besides that during the scope of the project following automation activities have been carried out:

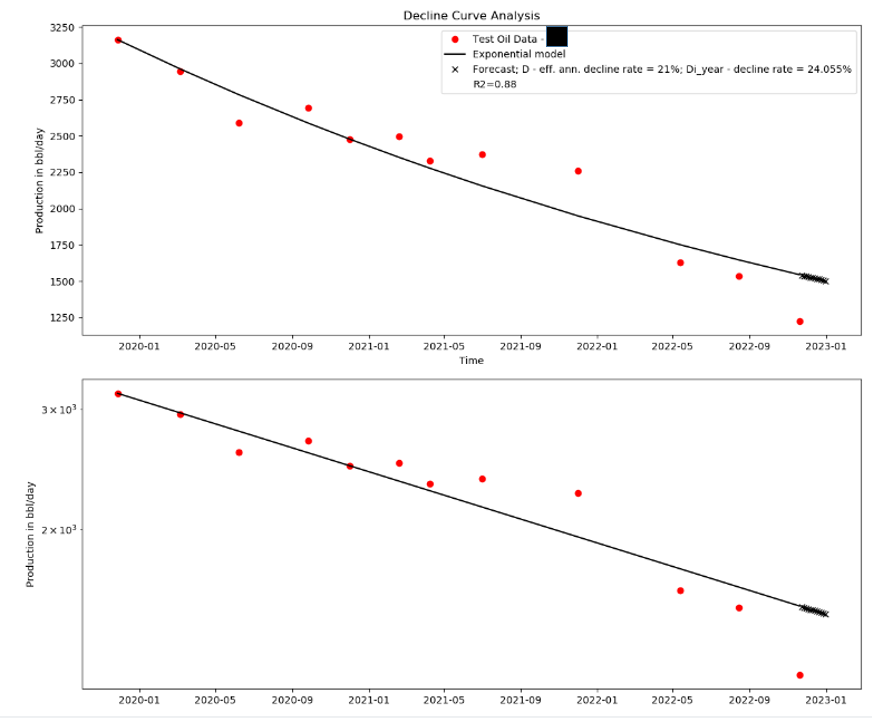

- Previously, the client was using excel based tool to implement Decline Curve Analysis. As recent data was not automatically uploaded to the excel file it was hard to maintain it with recent data and was causing to spend a lot of time for data collection. Python-based Decline Curve Analysis tool has been developed by our team and deployed in the internal software database system of the client where recent data can automatically be transferred to the tool and analysis can be done.

- Digital Excel-based reporting pages have been created for analysis of the performance of water injection wells, including their rates, formations they are injecting, pressure limits, additional comments etc. Dynamic data is transferred to the page automatically.

- CRI The tool has been developed to demonstrate the relationship between the downhole pressure of Cutting Re-Injection (CRI) wells and B and C annuli of oil-producing wells. It has been deployed in the internal software database system of the client where data comes and calculations are done automatically The tool helps engineers to detect any unusual pressure behavior spending less time

- Python scripts have been developed to interconnect Prosper, GAP models and excel files to carry out the prediction of injection and flowback rates for planned gas injection well. It reduced 16 hours of engineer job to 30 minutes and enabling to run more scenarios.