MZI` s Internal Control Valve (ICV) Performance Monitoring

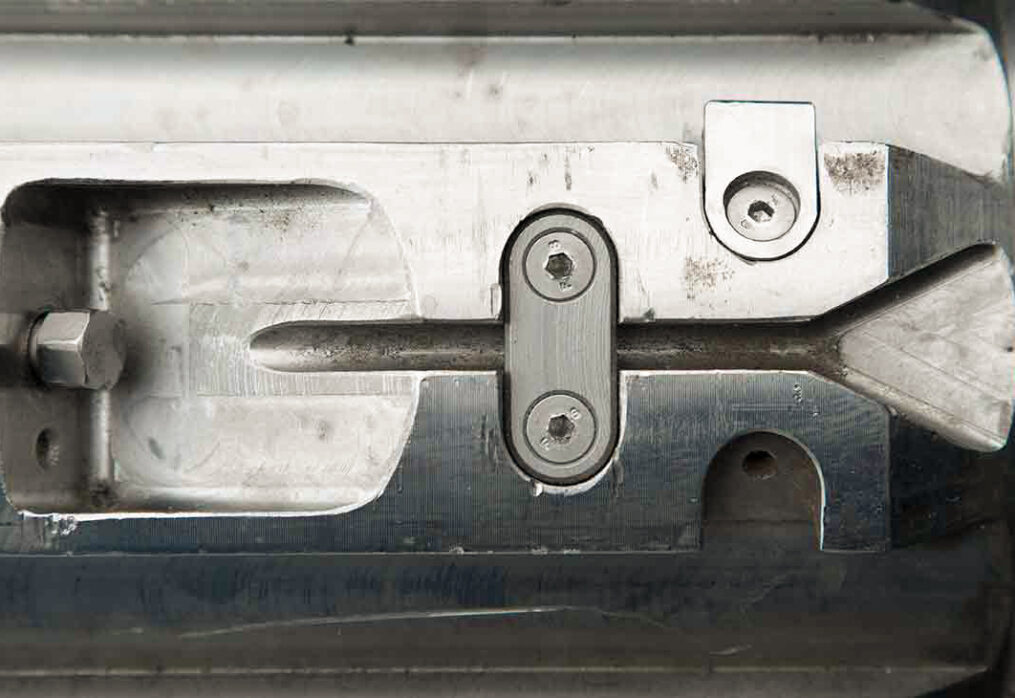

Control valves may be the most important, but sometimes the most neglected, part of a control loop. A control valve is used to control the rate of flow in a line. The “controller” receives the pressure signals and compares them with pressure drop for the desired flow and if it is different, it adjusts the control valve to increase or decrease the flow.

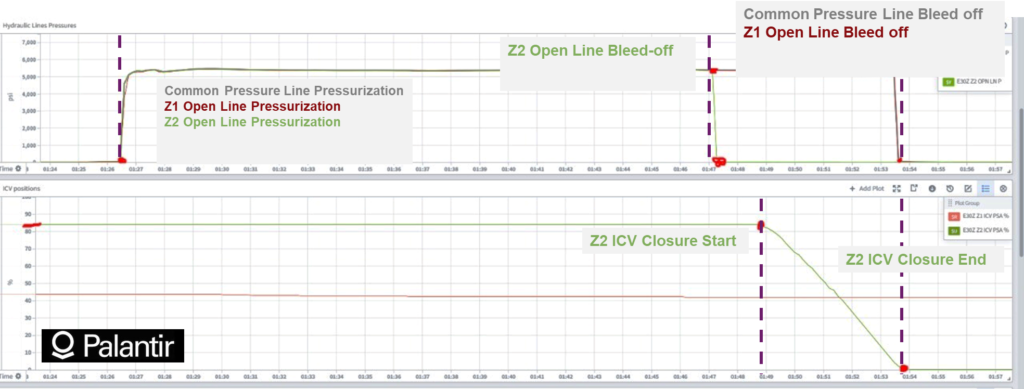

But sometimes Internal control valve (ICV) performance of multizone injector (MZI) wells deteriorates with time resulting in complete zonal failures. It is important to monitor ICV performance to foresee and mitigate these events. Key performance indicators (KPIs) of ICV performance include a detailed inspection of pressure lines, ICV positions, injection rates, etc. These are labor-intensive and routine work. We have built an algorithm that can identify each closure event and perform an analysis of the required KPI to evaluate ICV performance. An algorithm also provides a summary table for each closure event with a dashboard that makes the evaluation process much faster and more interactive.

A Palantir-based toolkit was used in this project to automate and standardize ICV Performance. Creating and deploying a custom algorithm on Palantir has many advantages:

- Identify each closure event

- Identify start and end times of common and open lines pressurization and bleed off

- Identify individual ICV closure start and end times, hence the closure duration

- Capture and display all closure-related statistics on custom Slate dashboards

The given product eliminates manual input and visual inspection. Additionally, it increases the predictability of ICV failures, minimizes consequences, and gives insights on ICV operations.