Automation of Annulus Pressure Monitoring

Sustained casing pressure (SCP), defined as excessive casing pressure that constantly rebuilds after bleed-down, is undesirable and sometimes potentially dangerous for producing wells. It is a complicated phenomenon which cannot be described only with annulus pressure build-ups without integrated analysis of temperature and other pressure effects. It is important to monitor the annulus pressures constantly and detect those build-ups once they have occurred. However, there is no mechanism that can detect those specific increases and warn engineers about possibly dangerous situations beforehand or at least after some time pressure measurements began fluctuating. Besides, manual tracking of oil and gas fields with a number of wells exceeding hundreds is not feasible. To summarize, there are 3 main reasons behind project initiation:

• No algorithmic solution for identification of SCP without direct well intervention

• The need for improved monitoring & detection

• Impossibility of tracking and analyzing 100+ wells annulus pressure measurements simultaneously

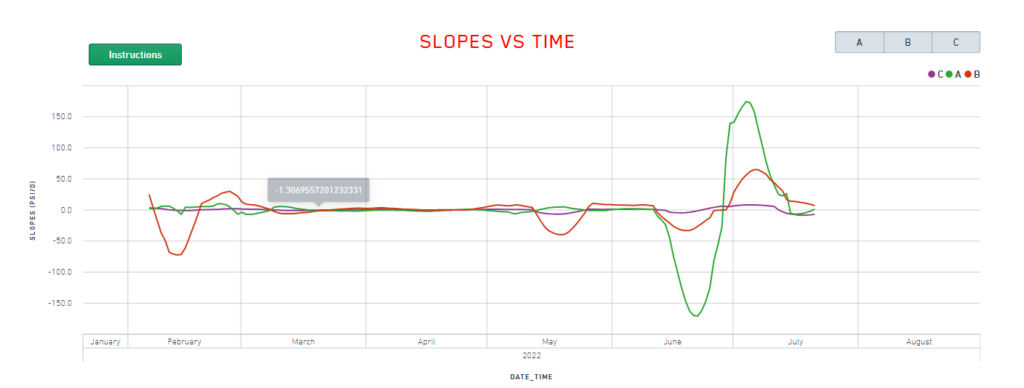

Note, that the tool developed during the project is not for the detection of SCPs directly rather it is for improved monitoring of annulus pressures and detection of build-ups. The framework provided allows engineers to separate build-ups caused from downhole pressure and temperature effects and to pay attention to specific ones.

The objective of developing the tool has been to improve the monitoring of annulus pressures and the detection of build-ups with minimum input by engineers. The tool allows engineers to easily separate build-up events caused by downhole pressure and temperature effects and to pay more attention to specific problematic ones.

In order to determine the relationship between different parameters, Pearson’s correlation coefficient has been used. The correlation coefficient varies between -1 and 1:

• 1 indicates a perfect direct relationship (the closer to 1 the stronger is the relationship)

• -1 indicates a perfect inverse relationship (the closer to -1 the stronger is inverse the relationship)

• Zero indicates no relationship at all (values from -0.3 to 0.3 can be treated as no/weak correlation)

In addition, the tool also demonstrates the relationship between the downhole pressure of Cutting Re-Injection (CRI) wells and B and C annuli of oil-producing wells. If there is

the direct relationship between CRI wells and producers, engineers can observe this with Pearson’s correlation coefficient.

The tool minimizes the work done by the engineer giving information about potential build-ups for different time periods and increasing success for well integrity with improved monitoring and detections. It reduces analysis time and makes it possible to track and analyze around 200 wells of annulus pressure measurements simultaneously.